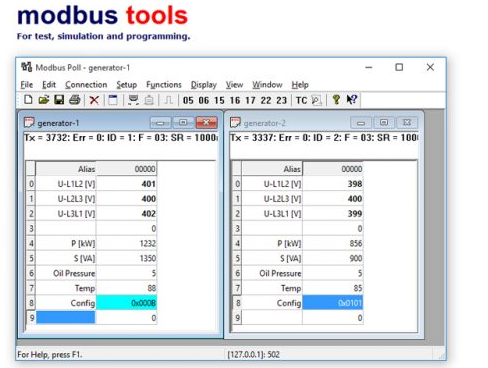

Modbus Slave 9 With License Key

Modbus Slave application involves implementing the Modbus communication protocol, typically over serial communication or Ethernet. Modbus is a widely used protocol in industrial automation for communication between electronic devices. Modbus supports different variants, including Modbus RTU (over serial) and Modbus TCP (over Ethernet). It also enables easy integration with existing industrial automation systems. Modular design allows for the addition of new devices without disrupting the entire system. It provides real-time access to critical data from connected devices. Allowing for prompt decision-making and control.

Uses of this app:

It also supports interoperability with a wide range of industrial devices and systems that comply with the Modbus protocol. Adherence to the Modbus standard ensures compatibility with a variety of hardware and software implementations. Modbus is a simple and cost-effective communication protocol, making it suitable for a broad range of industrial applications. Allows for easy scalability by adding or removing devices from the Modbus network as needed.

Advantages:

- It also offers a reliable communication method. Particularly in industrial environments where robustness is crucial.

- Modbus is an open protocol that promotes accessibility and avoids vendor lock-in. This openness facilitates the development of diverse solutions.

- Optimized resource utilization. Make it suitable for devices with limited processing power or memory.

- Plus, it also supports diagnostic features, aiding in troubleshooting and maintenance.

- Modbus also facilitates interoperability among devices from different manufacturers.

- It also simplifies debugging and testing processes due to the availability of various Modbus diagnostic tools and simulators.

- It also offers efficient data logging capabilities. Allowing users to track and analyze historical data for better insights into system performance.

Why did users choose this app?

- Provides a high degree of customization. Allowing users to tailor the Modbus Slave settings and configurations to match the specific requirements of their industrial processes.

- It also enables users to remotely monitor and control connected devices. Provide flexibility and convenience for managing industrial processes from different locations.

- Ensure seamless integration with legacy systems. Allows users to modernize their industrial processes without the need for a complete overhaul of existing infrastructure.

- Plus, it also offers low-latency communication. Ensuring that data exchange between the Modbus Slave and Master devices occurs with minimal delay is critical for time-sensitive applications.

- Incorporates energy-efficient communication protocols, contributing to reduced power consumption and operating costs.

- This also includes advanced diagnostics and health monitoring features, enabling users to proactively identify and address potential issues before they impact system performance.

- It also implements advanced security measures, such as encryption and authentication, to safeguard sensitive industrial data against unauthorized access or cyber threats.

Pros:

- Facilitates real-time monitoring of industrial processes, allowing users to promptly react to changes and optimize operations.

- Simplifies the process of updating firmware for connected devices, while also providing users with the latest features, improvements, and security patches.

- Utilize advanced data compression techniques, optimizing bandwidth usage and reducing the time required for data transmission over the Modbus network.

- Adapts to changes in network configurations seamlessly, ensuring also uninterrupted communication even in dynamic industrial environments.

Features:

User Role Management:

Implements robust user role management features, allowing administrators to define access levels and permissions for different users based on their roles within the organization.

Energy Consumption Analytics:

Provides detailed analytics on energy consumption, enabling users to identify energy-intensive processes and implement measures to improve efficiency.

Multi-Language Support:

Offers multi-language support at the user interface, catering to a diverse user base and making the application accessible to users worldwide.

Predictive maintenance integration:

Integrate seamlessly with predictive maintenance systems, helping users anticipate equipment failures and schedule maintenance activities proactively.

Enhanced Data Compression:

It also utilizes advanced data compression techniques, optimizing bandwidth usage and reducing the time required for data transmission over the Modbus network.

Minimal Downtime during Updates:

Minimizes downtime during software updates, allowing users to apply patches or new features without disrupting ongoing production processes.

Conclusion:

In conclusion, your Modbus Slave application stands out as a robust and user-friendly solution for industrial automation. By offering real-time monitoring, responsive technical support, and easy firmware updates, it also ensures that users can efficiently manage and optimize their industrial processes. The application’s compatibility with a wide range of devices, adaptive network configuration, and comprehensive alarm system contribute to its flexibility and reliability in dynamic industrial environments.